I. Terms and Definitions

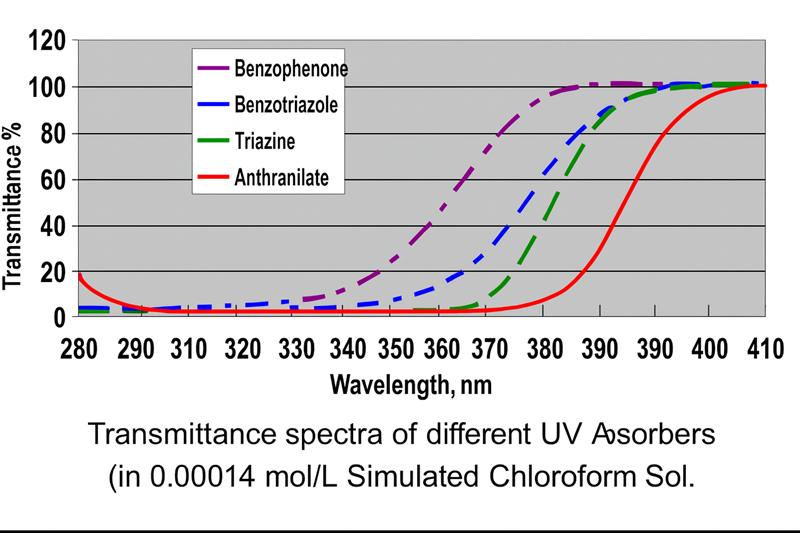

Sunlight contains a large amount of ultraviolet (UV) light, with wavelengths of approximately 290-460 nm, which is harmful to colored objects. This harmful UV light causes color molecules to decompose and fade through a chemical redox reaction. Using UV absorbers can effectively prevent or reduce the damaging effects of UV radiation on protected objects .

A UV absorber is a light stabilizer that absorbs the UV portion of sunlight and fluorescent light sources without undergoing any change itself. Under sunlight and fluorescence, plastics and other polymers undergo auto-oxidation reactions due to the action of UV radiation, leading to polymer degradation and deterioration, resulting in poor appearance and mechanical properties. Adding UV absorbers selectively absorbs this high-energy UV radiation, converting it into harmless energy that is released or consumed. Since different polymers have different UV wavelengths that cause degradation, different UV absorbers absorb different wavelengths of UV radiation. Therefore, the appropriate UV absorber should be selected based on the type of polymer used.

II. Classification and Functions of Ultraviolet Absorbers

Ultraviolet absorbers should meet the following conditions:

① It can strongly absorb ultraviolet rays (especially ultraviolet rays with wavelengths of 290~400nm); ② It has good thermal stability and will not change due to heat even during processing, with low thermal volatility; ③ It has good chemical stability and will not react adversely with the material components in the product ; ④ It has good miscibility and can be evenly dispersed in the material without blooming or seepage; ⑤ The absorbent itself has good photochemical stability, does not decompose, and does not change color; ⑥ It is colorless, non-toxic, and odorless; ⑦ It is washable; ⑧ It is inexpensive and readily available.

| Commonly used ultraviolet absorber categories | ||

| name | category | effect |

| UV absorber 327 | Benzotriazoles | Absorbs ultraviolet light in the 270~380nm range |

| UV absorber 531 | Benzophenones | Absorbs ultraviolet light in the 270~330nm range |

| UV absorber 1164 | Triazine | Absorbs ultraviolet light in the 300~380nm range |

| Light stabilizer 622/UVG | Hindered amines | Antioxidant, synergistic effect with UV absorbers |

Benzotriazole UV absorbers are currently the most widely used type in China, but triazine UV absorbers show significantly better performance than benzotriazoles. Triazine absorbers possess excellent UV absorption properties, along with other advantages, making them widely applicable in polymers. They exhibit excellent thermal stability, good processing stability, and acid resistance. In practical applications, triazine UV absorbers show a strong synergistic effect with hindered amine light stabilizers; when used together, they produce better results than when used individually.

III. Several common ultraviolet absorbers

(1) The reaction products of o-nitroaniline and p-cresol

It appears as colorless or pale yellow crystals. It is soluble in many organic solvents such as gasoline, benzene, and acetone. It has very low solubility in water and is not decomposed by concentrated alkalis or acids. It can react with heavy metal ions to form salts. It can absorb ultraviolet light with wavelengths of 270-280 nm. Its melting point is 130-131℃.

It is mainly used in resins such as polyester, chlorinated polyester, cellulose acetate, polyvinyl chloride, polystyrene, plexiglass, and polyacrylonitrile. It exhibits better stability in transparent products than in colored products. The dosage in finished products is ≤0.5%.

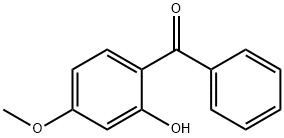

(2) 2-Hydroxy-4-methoxybenzophenone (UV-9)

A pale yellow or white crystalline powder. Density 1.324 g/cm³. Melting point 62-66℃. Boiling point 150-160℃ (0.67 kPa), 220℃ (2.4 kPa). Soluble in most organic solvents such as acetone, ketones, benzene, methanol, ethyl acetate, methyl ethyl ketone, and ethanol; insoluble in water. Solubility (g/100g, 25℃) in some solvents is as follows: benzene 56.2, n-hexane 4.3, ethanol (95%) 5.8, carbon tetrachloride 34.5, styrene 51.2, DOP 18.7.

As a UV absorber, it is suitable for various plastics such as polyvinyl chloride, polyvinylidene chloride, polymethyl methacrylate, unsaturated polyester, ABS resin, and cellulose resin. The maximum absorption wavelength range is 280~340nm, and the typical dosage is 0.1%~1.5%. It has good thermal stability and does not decompose at 200℃. This product absorbs almost no visible light, making it suitable for light-colored, transparent products. It can also be used in paints and synthetic rubber.

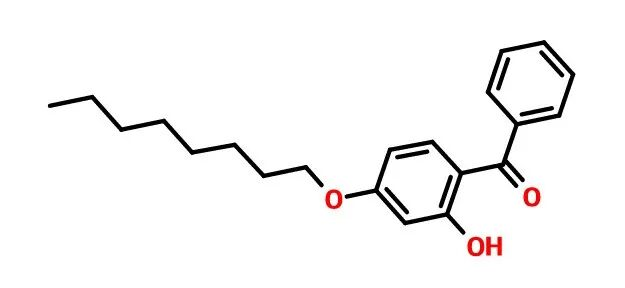

(3) 2-Hydroxy-4-n-octyloxybenzophenone (UV-531)

Pale yellow or white crystalline powder. Density 1.160 g/cm³ (25℃). Melting point 48~49℃. Soluble in acetone, benzene, ethanol, and isopropanol; slightly soluble in dichloroethane; insoluble in water. Solubility (g/100g, 25℃) in some solvents is: acetone 74, benzene 72, methanol 2, ethanol (95%) 2.6, n-heptane 40, n-hexane 40.1, water 0.5.

As a UV absorber, it strongly absorbs ultraviolet light with wavelengths of 270-330 nm. It can be used in various plastics, especially polyethylene, polypropylene, polystyrene, ABS resin, polycarbonate, and polyvinyl chloride. It has good compatibility with resins and low volatility. The typical dosage is 0.1% to 1%. It has a good synergistic effect when used with a small amount of 4,4-thiobis(6-tert-butyl-p-cresol). This product can also be used as a light stabilizer in various coatings.

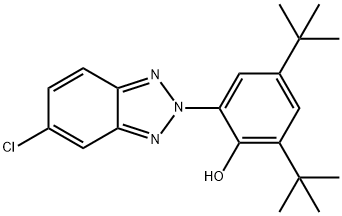

(4) 2-(2′-hydroxy-3′,5′-di-tert-phenyl)-5-chlorobenzotriazole (UV-327) is a UV absorber with similar properties and uses to benzotriazole UV-326. It strongly absorbs ultraviolet light with wavelengths of 270~380nm, has good chemical stability, and very low volatility. It has good compatibility with polyolefins. It is particularly suitable for polyethylene and polypropylene. In addition, it can also be used in polyvinyl chloride, polymethyl methacrylate, polyoxymethylene, polyurethane, unsaturated polyester, ABS resin, epoxy resin, cellulose resin, etc. This product has excellent heat sublimation resistance, washability, gas fading resistance, and mechanical property retention. It has a significant synergistic effect when used with antioxidants. It is used to improve the thermo-oxidative stability of products.

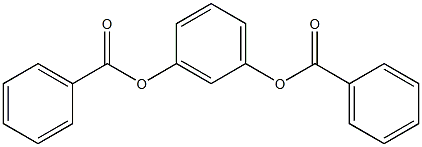

(5) Resorcinol monobenzoate is a white crystalline powder. Melting point 132~135℃. Bulk density 0.68 g/cm³ (20%). Soluble in acetone and ethanol, slightly soluble in benzene, water, n-heptane, etc. As a UV light stabilizer, its performance is similar to that of benzophenone-based light stabilizers. It is mainly used in polyvinyl chloride, cellulose resin, and polystyrene, typically at a dosage of 1% to 2%.

Post time: Dec-05-2025